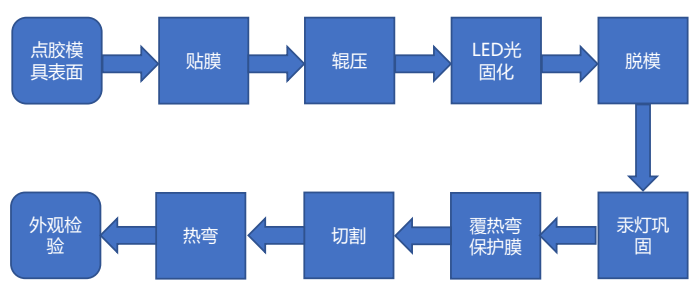

Product Features and Applications

Product features

Low viscosity, low energy curing;

Good toughness, good bending property, no cracking in hot bending;

Good solvent resistance, excellent abrasion resistance, alcohol abrasion resistance up to 800 times (with texture),

Can be applied to external textures;

Excellent adhesion, 100 ℃ * 1h, Baige test 5B

| Project | AT3611-17 |

| Appearance | Colorless or amber transparent liquid |

| Viscosity (cps @ 23 ℃) | 150 ~ 500 (adjustable) |

| Coating thickness (um) | 9 ~ 13 |

| Hardness (Shore D) | 80 |

| Alcohol abrasion resistance | 500g, 800 times, no scratches and chromatic aberration |

| -0.95 |

| Boiling performance (100 ℃ * 1h) | 5B |

| Flexibility (? 6mm) | No crack |

| Curing energy (LED, mJ/cm2) | 1000 ~ 120 |

Curing energy (mercury lamp, mJ/cm2)

| 800 ~ 1000 |

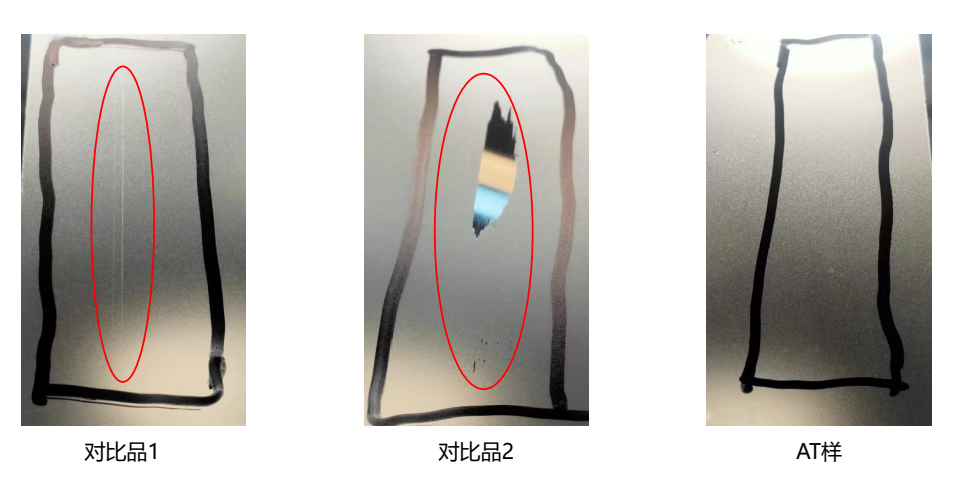

Comparison of wear resistance of products

Remark: The abrasion resistance test method is as follows: 95% alcohol, 500g weight, AATCC standard dry and wet rubbing white cotton cloth, 800 times.

After 800 alcohol abrasion tests, the appearance of AT sample has no obvious change, while the contrast sample has scratches of varying degrees, even worn through.

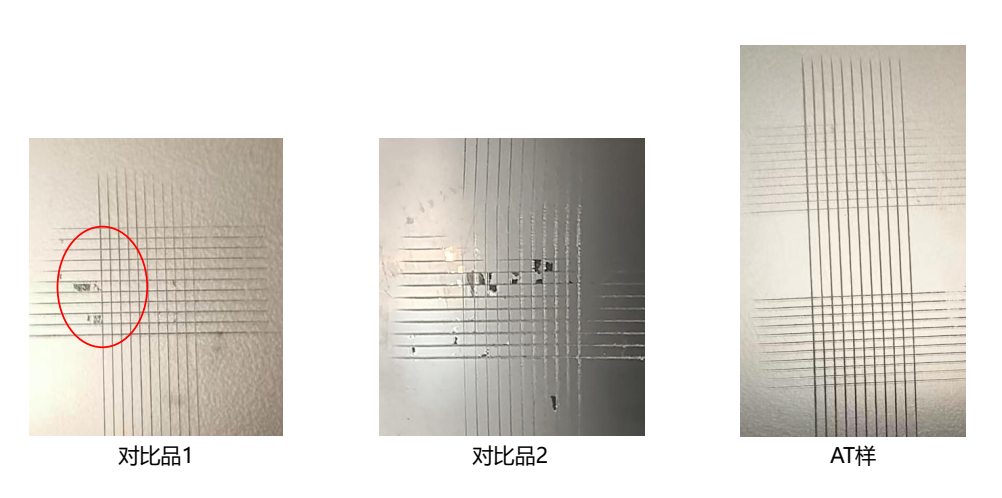

Comparison of boiling performance

Remark: After 100 ℃ * 1h, cool down to room temperature, and conduct 100 grid test. The test substrate is PC。

After 100 ℃ * 1h water boiling, AT sample baige test showed no shedding, while the control sample showed varying degrees of shedding.

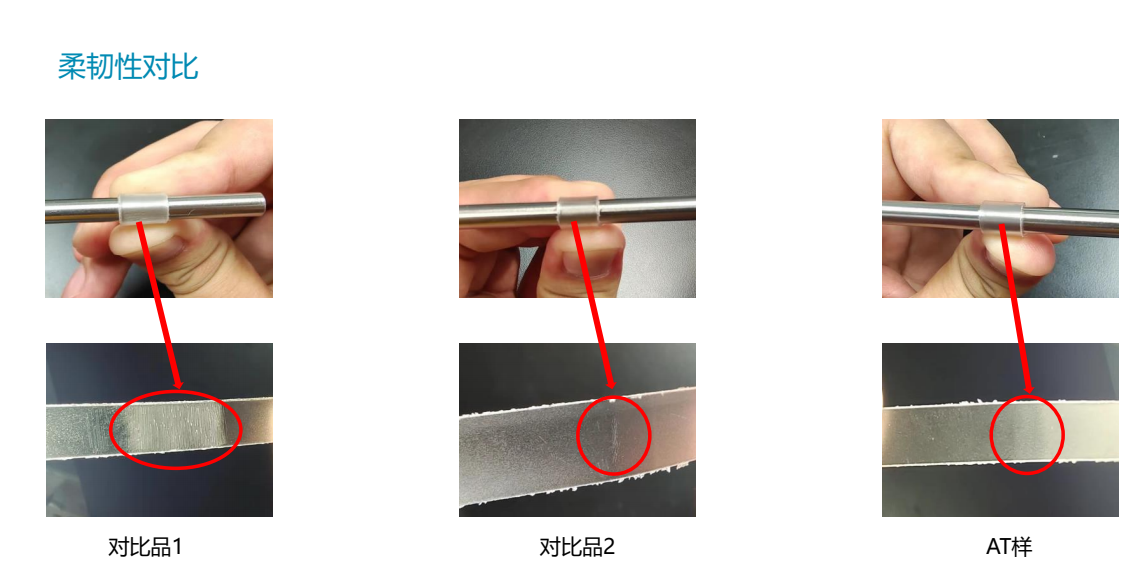

Flexibility comparison

Remark: metal bar diameter 6mm; The coating thickness is 10~15um, and the base material is PC.

An iron bar with a diameter of 6mm was used for the flexibility comparison experiment. After the experiment, the AT sample had no cracks, and the comparison samples 1 and 2 had cracks of varying degrees.